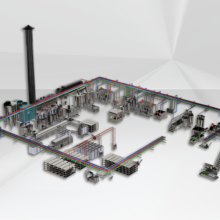

Personal Care & Disinfection Unit are typically composed of several machines that work together to produce the final product. The process typically begins with a mixing machine, which combines the ingredients for the detergent or shampoo. This mixture is then passed through a homogenizer, which ensures that the ingredients are evenly distributed throughout the mixture. The mixture is then heated and cooled in a pasteurizer before being pumped into a filling machine, where it is packaged into bottles or other containers. Finally, the containers are labeled and sealed before being shipped out to customers.

To guarantee the high-quality production of personal care and disinfection units, it is crucial to source superior materials and components. It’s also imperative to maintain all machinery meticulously and perform regular calibrations for optimal performance. Moreover, an efficient quality control system is indispensable for identifying and rectifying any product issues prior to reaching our valued customers.

Several factors need close attention in the production of personal care and disinfection units to ensure outstanding results. This includes the usage of safe ingredients, the selection of suitable packaging materials, appropriate labeling, adherence to strict sanitation standards, and ensuring ideal storage conditions for the finished products. The potential environmental implications associated with the production process should also be conscientiously evaluated and mitigated.

Personal Care & Disinfection Unit

We take pride in our years of experience in fabricating Personal Care & Disinfection Units for our global clientele. Our commitment to using only superior-grade materials and components is reflected in every product. Furthermore, we employ cutting-edge automation technologies to augment our production efficiency and precision. Our seasoned engineers are well-equipped to provide bespoke solutions designed exclusively to cater to your needs. Throughout this process, our dedicated customer service team will work tirelessly to ensure your satisfaction at every juncture.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

HOMMAK Makine developed the Hommix Powder-Liquid Blender as a result of long R&D studies.

Centrifugal pumpis a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors, called impellers.

We offer high quality, and reliable manufacturing services. We have experience with a wide variety of applications such as dairy, food & beverage, chemical & petrochemical, cosmetics, biotechnology, and pharmaceutical industries.

Building designs and machinery layouts are done according to the investor’s target capacity. These designs are also turned into a workflow system with diagrams according to the desired product specifications.