Plant paint preparation encompasses a process of crafting a homogenous mixture of various elements like pigments, binders, solvents, and additives, used widely in industrial painting. Key equipment used includes mixers, homogenizers, dispersers, and more specialized machinery, all of which must be closely monitored for precise ingredient proportions and optimal mixing.

The machinery used significantly influences the final product quality. Reliable, high-grade mixers and homogenizers are indispensable to ensure all ingredients are evenly incorporated. Dispersers also play a pivotal role in particle distribution. For certain specific applications, specialized equipment like high-pressure homogenization or emulsification might be necessary.

High-pressure homogenization, an essential facet of plant paint preparation, assists in the particle size reduction for better dispersion throughout the mixture. It aids in limiting particle size variation, thereby ensuring a uniform finish upon application. Furthermore, it reduces air bubbles that could potentially cause defects in the final product.

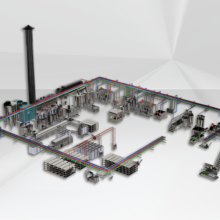

Plant Paint Preparation Unit

Selecting our company for your plant paint preparation needs guarantees the provision of superior machinery and equipment, all competitively priced. Our team, comprising experienced engineers, offers customized solutions for your specific needs, ensuring you attain optimal results from your plant paint preparation process. Additionally, we offer an ongoing support and maintenance service, giving you the peace of mind that your machinery will remain in peak condition for years to come.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

High-pressure pumps are ideal for transferring high density and viscosity products. It is used as the feeder for the tower in the production of milk powder, food powders, chemical powders, and other powder types.

Storage tanks are made of stainless steel for the storage of liquid substances.

We offer high quality, and reliable manufacturing services. We have experience with a wide variety of applications such as dairy, food & beverage, chemical & petrochemical, cosmetics, biotechnology, and pharmaceutical industries.

Building designs and machinery layouts are done according to the investor’s target capacity. These designs are also turned into a workflow system with diagrams according to the desired product specifications.