In the swiftly evolving realm of biotechnology, liposome production is a fundamental pillar, driving innovations in pharmaceuticals and therapeutic solutions. These minuscule, spherical vesicles have significantly altered drug delivery systems, fostering targeted treatments while minimizing adverse effects. At the heart of this transformation is the homogenizer, a crucial technology that guarantees the uniformity and stability of liposome formulations. This blog post explores the indispensable role of homogenizers in liposome production, with a special focus on the superior capabilities of Hommak homogenizers.

The Pivotal Role of Liposomes in Biotechnology

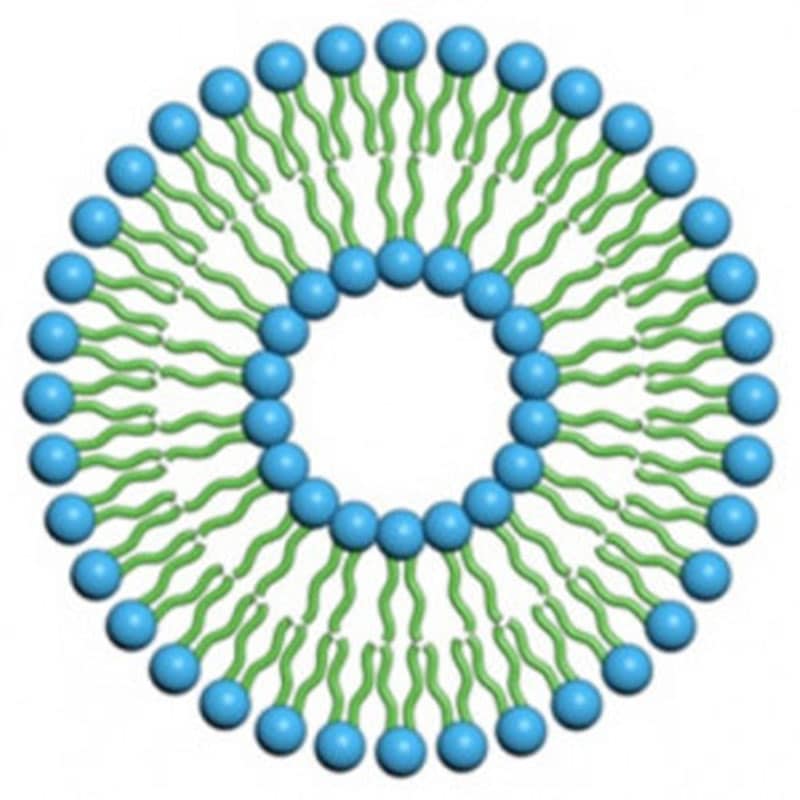

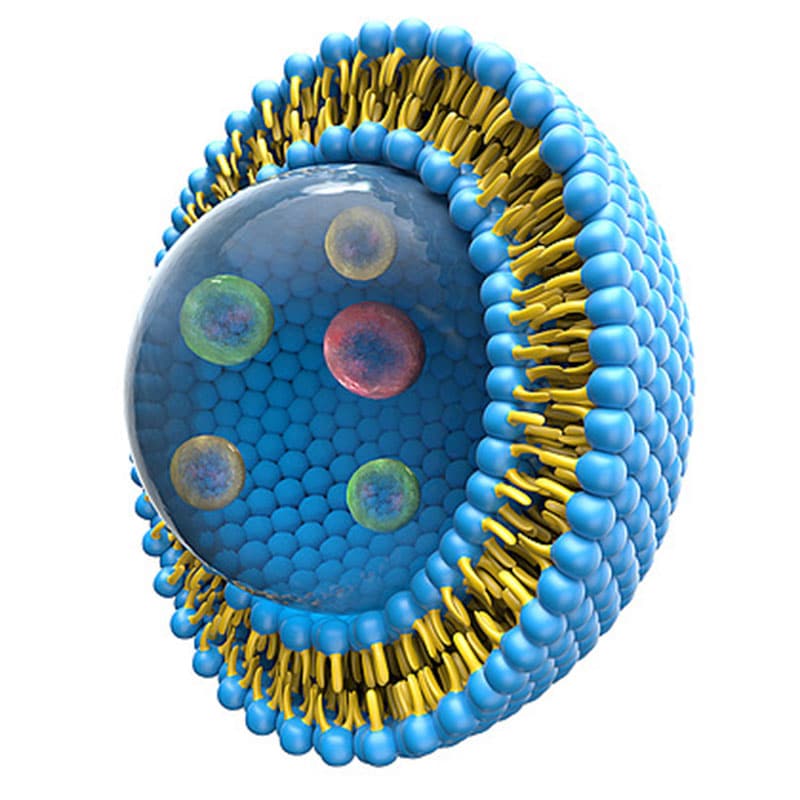

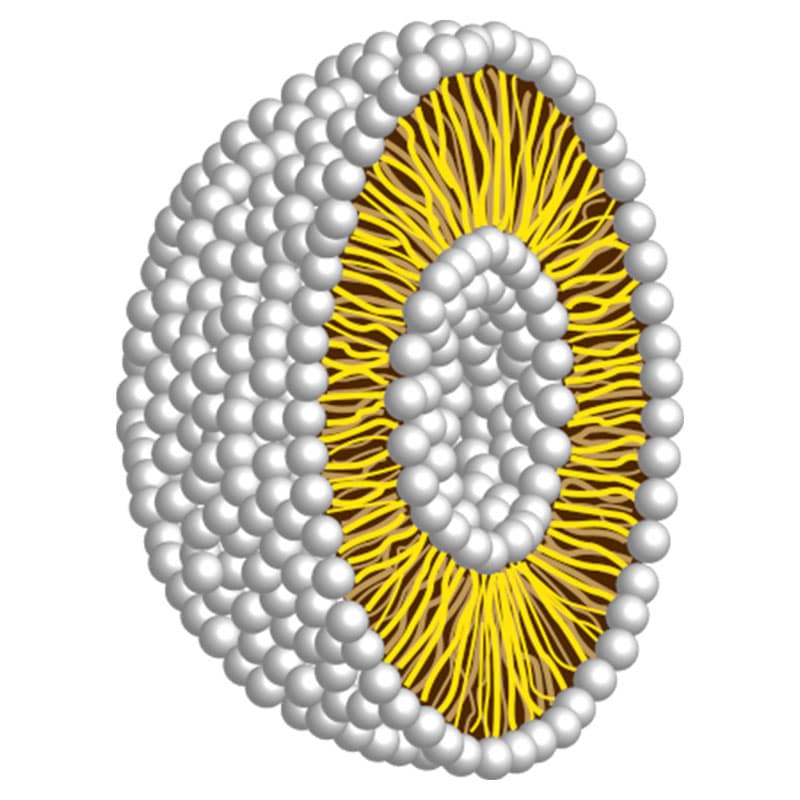

Liposomes, tiny vesicles composed of one or more phospholipid bilayers, have been instrumental in biotechnology since their inception. They play a vital role in drug delivery, gene therapy, and vaccine development, thanks to their biocompatibility and ability to encapsulate substances of varying polarity. In therapeutic contexts, liposomes improve drug efficacy by enhancing solubility, stability, and bioavailability, thereby revolutionizing the treatment of complex diseases.

Homogenizers: The Core of Liposome Production

Achieving precision, consistency, and efficiency in liposome production requires high-quality homogenizers. By applying mechanical force, homogenizers reduce lipid particles to a uniform size, a critical factor for the stability and functionality of liposomes. The size, charge, and composition of liposomes are crucial for their interaction within biological systems, highlighting the essential role of homogenizers in controlling these parameters.

The Superiority of Hommak Homogenizers

Hommak homogenizers stand out in the biotechnology field for several reasons:

Precision Control: Hommak’s advanced technology facilitates precise management of pressure and shear forces, enabling the production of liposomes with specific size distributions and characteristics.

Scalability: Hommak homogenizers deliver consistent performance across scales, from lab research to industrial production, proving indispensable for both experimental and large-scale pharmaceutical manufacturing.

Durability and Efficiency: Designed for long-term use with minimal maintenance requirements, Hommak’s machines offer an economical solution for ongoing production needs.

Versatility: Capable of processing a broad spectrum of materials, Hommak homogenizers support a wide array of applications beyond liposome production, making them a versatile asset in biotech research and manufacturing.

Conclusion

Homogenizers, especially those crafted by Hommak, play a critical role in liposome production. Their capacity to ensure product consistency, stability, and production efficiency is invaluable in the field of biotechnology. As we witness continuous breakthroughs in drug delivery and therapeutic methods, the significance of high-pressure homogenization technology becomes increasingly prominent. Hommak homogenizers, renowned for their precision, scalability, and adaptability, lead this technological revolution, significantly advancing biotech innovations.