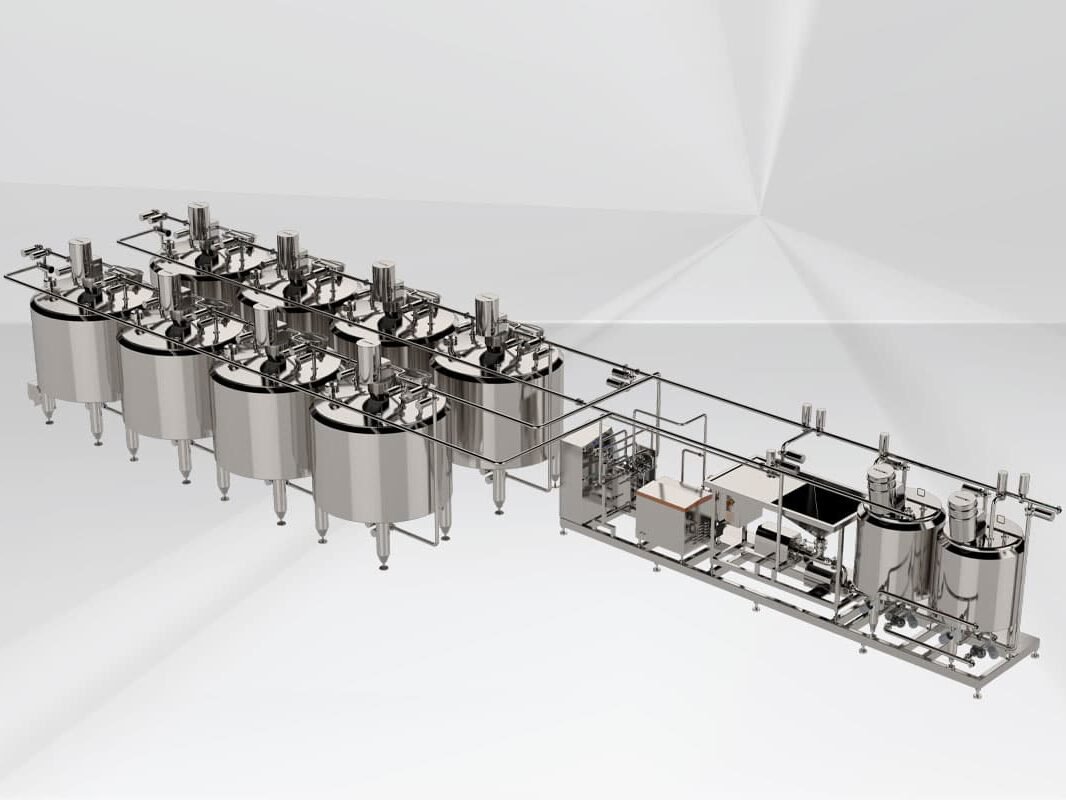

The machinery involved in an ice cream production facility includes:

- Freezing Equipment: Utilized to chill the ice cream mixture to the perfect temperature.

- Mixing Machines: These devices are used for combining all the ingredients that contribute to the ice cream’s distinct flavor and texture.

- Homogenizers: These are crucial for dividing the fat particles within the ice cream mixture to create a smooth and even texture.

- High-Pressure Homogenizers: They further refine the process of fat particle breakdown in the mixture, resulting in an ice cream texture that’s both smoother and more consistent.

- Pasteurizers: These are employed to heat the ice cream mixture to specific temperatures for eliminating potential pathogens, ensuring a safe and consumable product.

- Extrusion Equipment: These machines help shape the ice cream mixture into the desired sizes and forms.

- Packaging Equipment: The finished ice cream is then packaged into containers with the help of these machines.