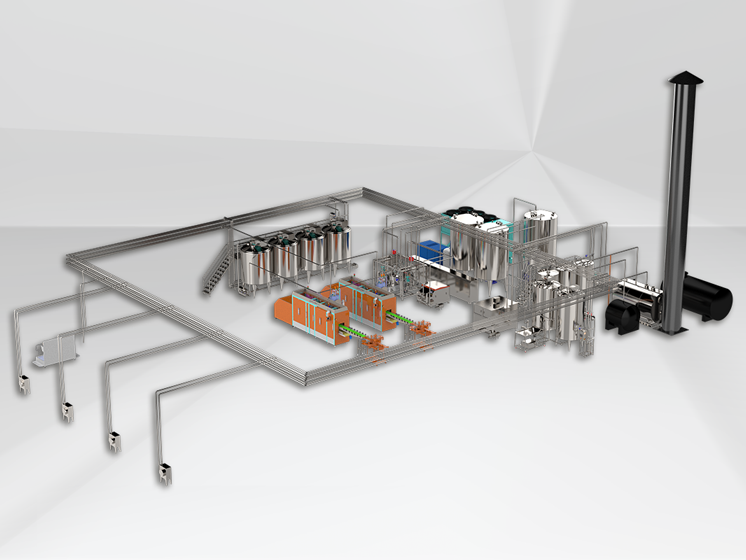

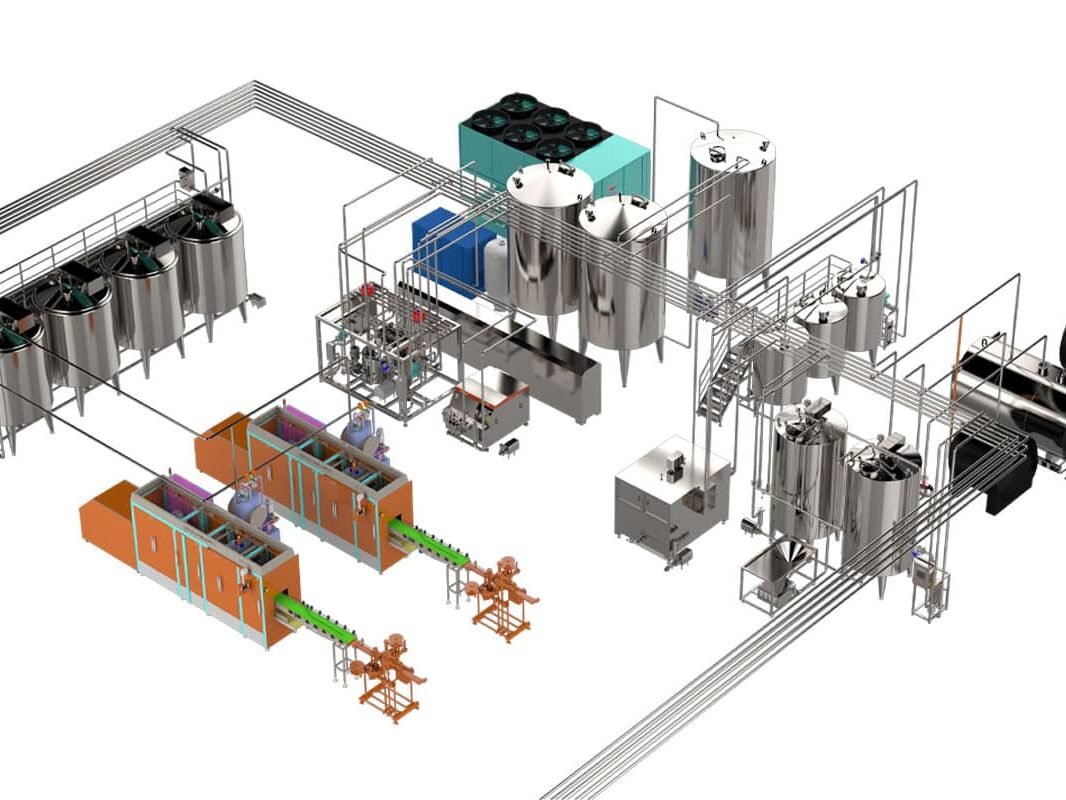

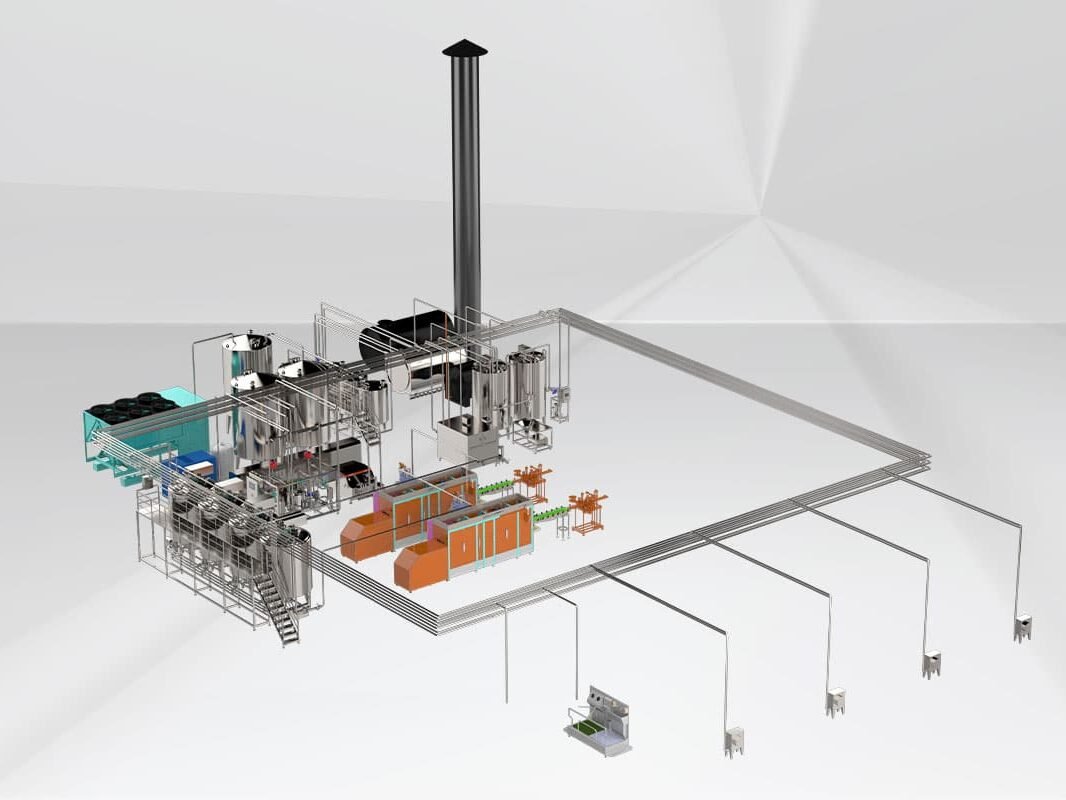

A yogurt production facility, or a yogurt plant, is an establishment that employs comprehensive machinery for the end-to-end manufacture of yogurt. This equipment set encompasses various machinery such as homogenizers, pasteurizers, fermentation tanks, filling and packaging machines, as well as cooling systems. These components are integral to the successful operation of a yogurt plant.

The yogurt production process initiates with the careful preparation of raw ingredients, which typically involves the blending of dairy products like milk and cream, with selected flavorings and sweeteners. To achieve a uniform and smooth consistency in the yogurt, homogenizers are employed to disrupt any large particles. Following this, the pasteurization stage is crucial to eliminate any potential bacterial presence in the yogurt mix. Post-pasteurization, the yogurt undergoes fermentation, after which it is cooled down and transferred into containers for packaging.

When you select our company for your yogurt production needs, you’re choosing industry-leading machinery and expertise for your facility.