Ensuring impeccable hygiene and safety in food and beverage production facilities is non-negotiable. Hommak steps up to this challenge by offering cutting-edge Clean In Place (CIP) systems, designed to meticulously cleanse the interiors of processing equipment such as tanks, pipelines, and pumps. Our automated CIP solutions embody the perfect amalgamation of chemical, mechanical, and thermal cleaning methods, promising an environment free from contamination and aligned with the highest cleanliness standards.

Essential Factors in Designing a CIP Plant

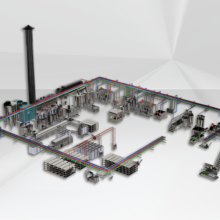

At the heart of our CIP solutions lie state-of-the-art high-pressure, high shear mixers, alongside essential components like pumps, storage tanks, valves, flow meters, and piping systems. Our pumps are engineered for optimal circulation of cleaning solutions, ensuring efficient and thorough cleaning cycles. Storage tanks serve as both reservoirs and mixing vessels for the cleaning agents, while our meticulously selected valves regulate fluid flow and maintain desired pressures. Accurate flow meters monitor the cleaning solutions’ movement, and our comprehensive piping systems facilitate their distribution throughout the system.

Design Principles for Maximum Efficiency

In designing our high-pressure, high shear mixer CIP systems, Hommak prioritizes the integration of equipment that excels in quality and suitability. Key considerations include flow rate, temperature control, and chemical compatibility, ensuring our systems are not only effective but also efficient. The performance of our CIP systems heavily relies on the precision-engineered pumps, which are selected for their optimal size and flow rate, enhancing cleaning efficacy. The careful choice of tanks, valves, and other components underlines our commitment to delivering a seamless, high-standard cleaning process tailored to food and beverage processing demands.

Choosing Hommak for Your CIP Plant Needs

Selecting the right partner for the installation and maintenance of your CIP plant is crucial. Hommak stands out as a leader in the field, backed by our profound knowledge and vast experience in CIP systems, especially those featuring high-pressure, high shear mixers. We offer bespoke CIP solutions, underpinned by expert advice and continuous support, ensuring your operations meet the highest hygiene standards. By entrusting us with your CIP plant needs, you gain a partner dedicated to the entire lifecycle of your system – from design and installation to routine maintenance and beyond.

Partner with Hommak to elevate your food and beverage production’s hygiene and safety standards, ensuring a spotless, efficient process with our advanced high-pressure, high shear mixer CIP systems.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

Storage tanks are made of stainless steel for the storage of liquid substances.

We offer high quality, and reliable manufacturing services. We have experience with a wide variety of applications such as dairy, food & beverage, chemical & petrochemical, cosmetics, biotechnology, and pharmaceutical industries.

Discover Hommak Mixing and Blending Systems, designed to meet the needs of the food processing, chemical and pharmaceutical industries.

Building designs and machinery layouts are done according to the investor’s target capacity. These designs are also turned into a workflow system with diagrams according to the desired product specifications.