Eggs are a versatile and widely used engredient in the food industry and their and uses range from baked goods to sauces and dressing. In industrial food production, eggs are often processed in large quantities an done of the most important steps in egg processing is homogenization. In this blog, we will explore the process of egg homogenization and the industrial uses of eggs.

What is Egg Homogenization?

Egg homogenization is a process that involves breaking down the egg yolk and white into small particles to create a smooth and consistent texture. This process is important in industrial egg processing, where processing, where large quantities of eggs are used. Homogenization helps to ensure that the eggs are consistent in texture and quality, which is important for producing high-quality food products.

There are several methods of egg homogenization, including mechanical homogenization and high pressure homogenization. In mechanical homogenization, the eggs are passed through a series of small opening to break them down into small particles.

Industrial Uses of Eggs

Eggs are used in a variety of ways in the food industry and their versatility makes them a valuable ingredient in many products. One of the most common uses of eggs is in baked goods, where they are used as a binding agent and to add moisture and texture. Eggs are also used in sauces and dressings, where they can add richness and flavor.

In addition to their culinary uses, eggs are also used in a variety of industrial applications. Egg whites are used in the production of vaccines and cosmetics, while egg yolks are used in the production of paints and adhesives. The proteins in eggs are also used in the production of various pharmacutical.

The Importence of Homogenization in Industrial Egg Processing

In industrial egg processing, homogenization is a crucial step in ensuring the consistency and quality of the final product. Without homogenization, the texture of the eggs can be inconsistent, which can affect the quality to the final product. Homogenization also helps to ensure thet any additives or ingredients are evenly distributed throughout the eggs.

In addition to improving the consistency of the eggs, homogenization also helps to improve the efficiency of the egg processing line. Homogenized eggs are easier to handle and transport and they can be used in a wider range of applications.

Conclusion

Egg homogenization is an important step in industrial egg processing and it plays a crirical role in ensuring the consistency and quality of the final product. Whether you are producing baked goods, sauces or industrial products, homogenization is an essential step in getting the most out of your eggs.

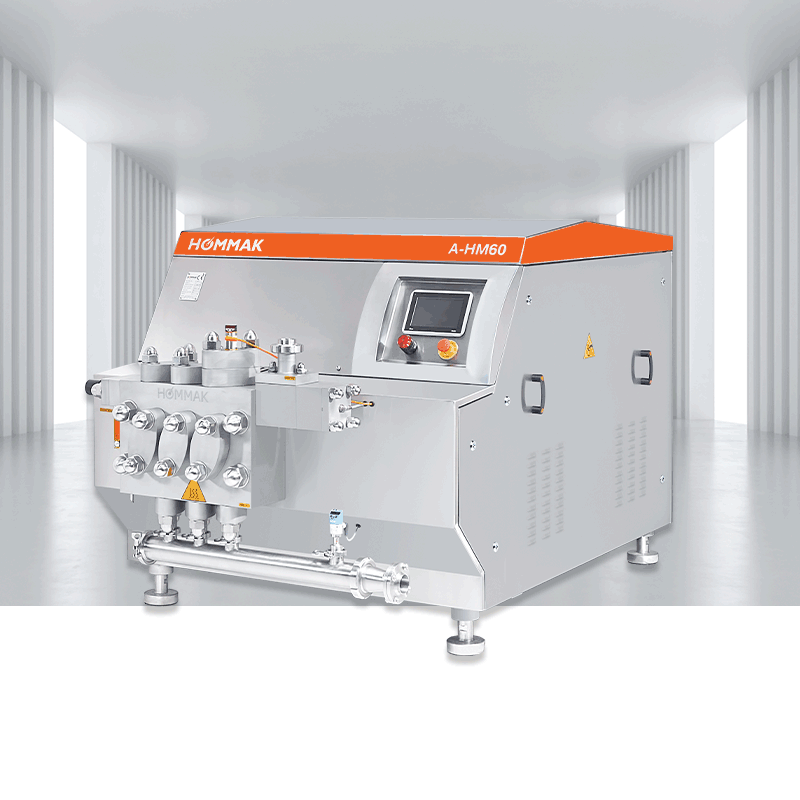

Homogenizers Used in Egg Processing Typically Have the Follwing Features

- High pressure capability: Egg homogenization typically requires high pressure homogenizers that can operate at pressure from 60 to 120 bar. (It can vary up to 500 bar depending on the process you need.)

- Temperature control: Egg products are sensitive to temperature changes, so homogenizers used in egg processing typically have precise temperature control mechanisms that ensure the product is not overheated or cooled quickly during processing.

- Multiple stages: Homogenizers used in egg processing typically have multiple stages to ensure thet the product is thoroughly homogenized and emulsifield.

- Sanitary desing: Homogenizers used in egg processing are typically designed for easy cleaning and sanitation to ensure that the product is free of contaminants.

- Variable speed drive: Homogenizeers used in egg processing typically have a variable speed drive that allows the operatör to adjust the processing speed to achieve the desired level of homogenization.