Renowned for crafting high-efficiency liquid fertilizer production lines, Hommak incorporates the latest technology to deliver top productivity. We cater to a diverse range of industries with our extensive selection of liquid fertilizer production lines, from agriculture to industrial applications.

A comprehensive understanding of liquid fertilizer components is essential for anyone seeking to optimize crop yields and decrease cultivation costs. Liquid fertilizers consist of a nitrogen, phosphorus, and potassium mix, supplemented with wetting agents, insecticides, herbicides, fungicides, trace elements, and other additives. Depending on the season, these liquid fertilizers are applied either during summer or winter. Typically, urea and ammonium nitrate solutions are sprayed on top of the soil, providing wide coverage.

Our liquid fertilizer production lines utilize a homogenization process that ensures the consistent quality of every batch by distributing the ingredients uniformly. This uniformity is crucial to the effectiveness of the fertilizer, as it promotes balanced nutrient distribution and thus, optimal plant growth. Furthermore, homogenization achieves an even particle size, essential for the efficient application of the liquid fertilizer.

Here at Hommak, we are devoted to supplying top-tier liquid fertilizer production lines designed to meet our clients’ needs. Our production solutions are engineered to maximize yield and cost efficiency, while concurrently minimizing environmental footprints. We take pride in offering our customers unparalleled products and services, aiding them in crafting the highest quality liquid fertilizers.

The agricultural industry is increasingly acknowledging the benefits of Organic Liquid Fertilizers. They offer an eco-friendly and sustainable solution to nourishing plants and crops. The manufacturing of Organic Liquid Fertilizer is an all-encompassing process that involves producing, homogenizing, achieving micron diameter, and spraying the fertilizer. We will delve into each of these stages and their contributions to the successful production of organic liquid fertilizers in the following discussion.

Homogenization plays a crucial role in the process of organic liquid fertilizer production. It involves breaking down the constituents into microscopic particles, allowing them to blend and disperse more easily. This guarantees a more uniform distribution of the fertilizer, thus optimizing plant and crop nutrition. Adequate homogenization prevents the fertilizer from clumping or settling in the soil, inhibiting the formation of harmful bacteria or fungi.

Moreover, the output of the organic liquid fertilizer production line can serve as a pesticide. As homogenization transforms the constituents into microscopic particles, they can disperse and cover more efficiently, providing robust protection against pests and diseases.

Micron diameter, indicating the particle size, is crucial in the spraying process of fertilizer production. A smaller micron diameter implies finer particles, thereby increasing the efficiency of the fertilizer.

Organic fermentation is another critical component in producing organic liquid fertilizers. It involves the breakdown and conversion of organic material into a liquid form, enhancing the nutrient delivery efficiency to plants and crops. Besides improving fertilizer quality, the fermentation process also aids in reducing odor.

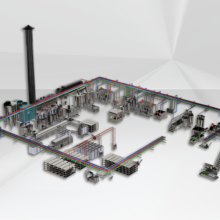

HOMMAK Liquid Fertilizer Production Line

Organic bacterial proliferation and fermentation are vital components in the production of organic liquid fertilizers. These processes boost the fertilizer’s potency and efficiency. The growth of bacteria facilitates the breakdown of organic matter, making it simpler to distribute and apply. Bacterial fermentation aids in converting the organic matter into a liquid form, simplifying its application and distribution.

Organic Liquid Fertilizers play a significant role in the agricultural sector. The production, homogenization, micron diameter measurement, and spraying stages are all critical to the successful manufacture of organic liquid fertilizer. This passage underscores the importance of these stages and their contribution to the successful creation of organic liquid fertilizer.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

HOMMAK Makine developed the Hommix Powder-Liquid Blender as a result of long R&D studies.

Storage tanks are made of stainless steel for the storage of liquid substances.

We offer high quality, and reliable manufacturing services. We have experience with a wide variety of applications such as dairy, food & beverage, chemical & petrochemical, cosmetics, biotechnology, and pharmaceutical industries.

Building designs and machinery layouts are done according to the investor’s target capacity. These designs are also turned into a workflow system with diagrams according to the desired product specifications.