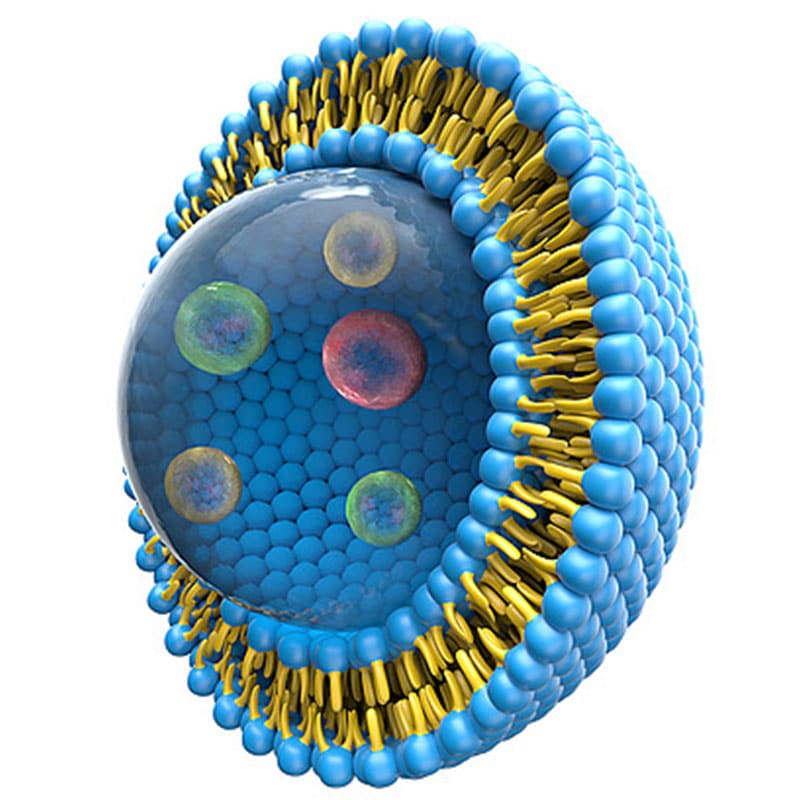

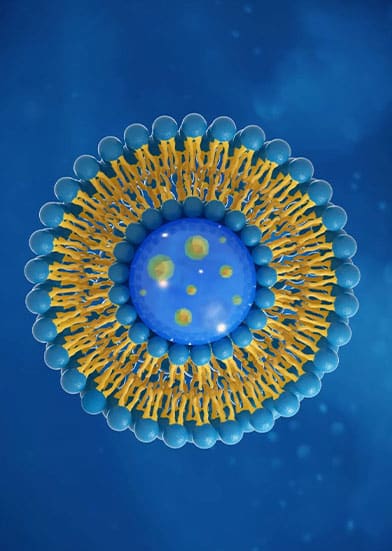

The pharmaceutical realm is witnessing a remarkable transformation, propelled by the integration of cutting-edge technologies that redefine drug delivery systems. At the forefront of this evolution is the strategic application of liposomes. Characterized by their spherical vesicle structure, composed of a phospholipid bilayer, liposomes are pivotal in drug delivery. Their unparalleled biocompatibility and versatile capability to encapsulate substances of varied hydrophilic and hydrophobic nature underscore their significance. Central to the efficient production of liposomes is the utilization of advanced homogenizers, with Hommak homogenizers standing out as a leading choice in the industry.

Revolutionizing Liposome Production with Hommak Homogenizers

Homogenizers are instrumental in crafting emulsions or suspensions, particularly in liposome manufacturing, where they play a critical role in reducing particle size. This ensures a consistent, stable liposome formulation. The homogenization process employs high pressure, shear, and occasionally ultrasonic waves to refine the consistency and enhance the stability of liposome preparations.

The Pivotal Importance of Homogenization in Liposome Manufacturing

Homogenization stands as a cornerstone in liposome production for multiple compelling reasons:

Size Reduction and Uniformity: It significantly diminishes lipid particle size, a crucial factor for uniform drug encapsulation and release.

Enhanced Stability: Homogenization fosters the stability of liposomes, extending their shelf life and preserving the effectiveness of the pharmaceutical product.

Scalability: The process accommodates scaling, fitting both experimental research and expansive commercial production seamlessly.

Controlled Drug Release: Through homogenization, liposome characteristics can be finely tuned, influencing the drug’s release dynamics.

Hommak Homogenizers: Pioneering Efficiency in Liposome Production

Hommak homogenizers emerge as a beacon of innovation and efficiency in the domain of liposome manufacturing, offering several distinct advantages:

Optimized Efficiency: Designed to excel in particle size reduction, Hommak homogenizers are pivotal for producing effective liposome formulations.

Scalability and Flexibility: Their versatility extends to various production volumes, from small batches to large-scale operations, ensuring adaptability across different production needs.

Consistent Quality: Hommak equipment guarantees uniform outcomes, essential for the quality and efficacy of pharmaceutical products.

User-Centric Design: Hommak prioritizes ease of use, simplifying the sophisticated process of homogenization for a broader range of users.

Conclusion

In the dynamic landscape of the pharmaceutical industry, the strategic application of homogenizers, especially Hommak homogenizers, is indispensable for the innovative production of liposomes. Their capability to ensure uniform, stable, and efficient liposome formulations positions them as a critical tool in advancing drug delivery technologies. As the sector progresses, the value of these technologies in enhancing patient care and treatment outcomes continues to grow, solidifying their role in the future of pharmaceutical development.