In the dynamic world of cosmetics and personal care, the science and technology behind product manufacturing are as crucial as the ingredients themselves. One of the unsung heroes in this process, particularly in shampoo production, is the homogenizer. Here, we delve into why homogenizers are indispensable in shampoo manufacturing and how Hommak homogenizers stand out in this vital role. Additionally, we’ll touch upon our own expertise in developing comprehensive shampoo production lines.

Understanding the Role of Homogenizers in Shampoo Production

Achieving Consistency and Stability:

The primary function of a homogenizer in shampoo production is to blend various ingredients into a consistent, stable mixture. Shampoos consist of an array of components like surfactants, conditioners, fragrances, and preservatives. Without proper homogenization, these ingredients could separate or settle, leading to an inconsistent product.

Enhancing Product Quality:

Homogenization not only ensures uniformity but also improves the quality of the shampoo. It breaks down particles and droplets, ensuring a smoother texture and better distribution of ingredients. This leads to a product that not only looks appealing but also performs better in terms of cleaning and conditioning hair.

Increasing Efficiency and Shelf-life:

A well-homogenized shampoo is more stable, which increases its shelf-life. This process also plays a role in enhancing the efficiency of the product, meaning that a smaller quantity can achieve the desired effect, offering cost-effectiveness to both manufacturers and consumers.

The Advantages of Hommak Homogenizers

Cutting-Edge Technology:

Hommak homogenizers incorporate advanced technology that ensures precise and consistent homogenization. This leads to a superior end product, maintaining the quality and effectiveness of the shampoo.

Customization and Flexibility:

Understanding the diverse needs of shampoo formulations, Hommak offers customizable solutions. Their homogenizers can be tailored to handle different capacities and types of ingredients, making them a versatile choice for manufacturers.

Energy Efficiency:

In an era where sustainability is key, Hommak’s energy-efficient design stands out. These homogenizers consume less power, reducing the environmental footprint of the manufacturing process.

Durability and Low Maintenance:

Hommak’s homogenizers are known for their durability and ease of maintenance. This reliability translates into fewer production halts and lower long-term costs.

Our Expertise in Shampoo Production Lines

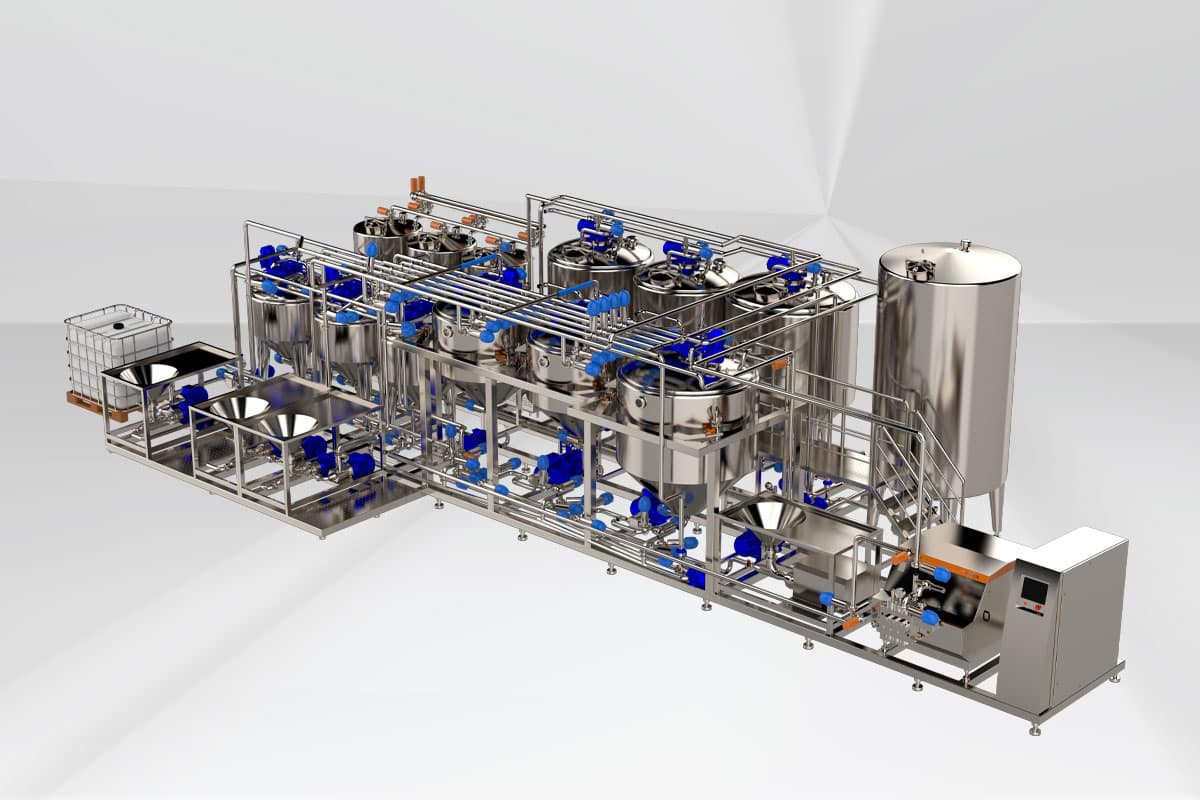

In addition to understanding the critical role of homogenizers like those from Hommak, our expertise extends to developing entire shampoo production lines. We integrate advanced technology and machinery, including Hommak homogenizers, to create systems that are efficient, cost-effective, and capable of producing high-quality shampoo. Our focus on customization allows us to meet the specific needs of our clients, whether it’s small-scale boutique brands or large-scale commercial producers.

Conclusion

The right homogenizer is key to producing a shampoo that stands out in the competitive market. Hommak homogenizers, with their advanced technology, customization options, energy efficiency, and durability, represent an excellent choice for manufacturers looking to enhance their product quality and efficiency. Coupled with our experience in crafting complete shampoo production lines, we are equipped to meet the evolving demands of the personal care industry.