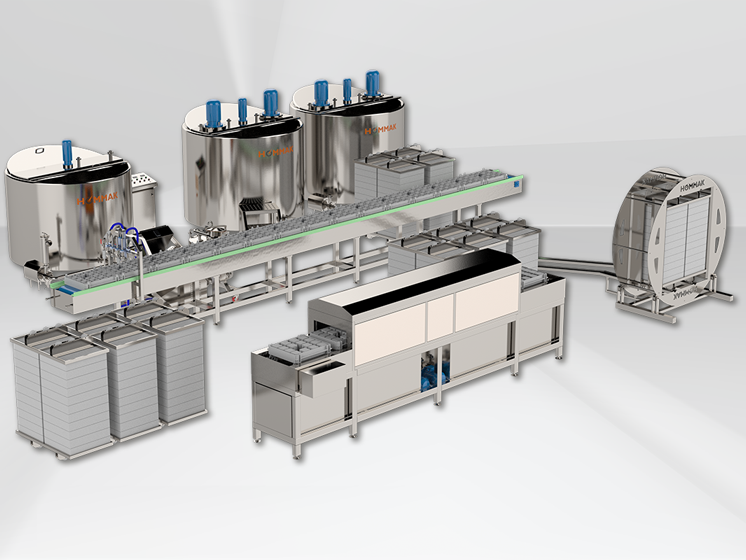

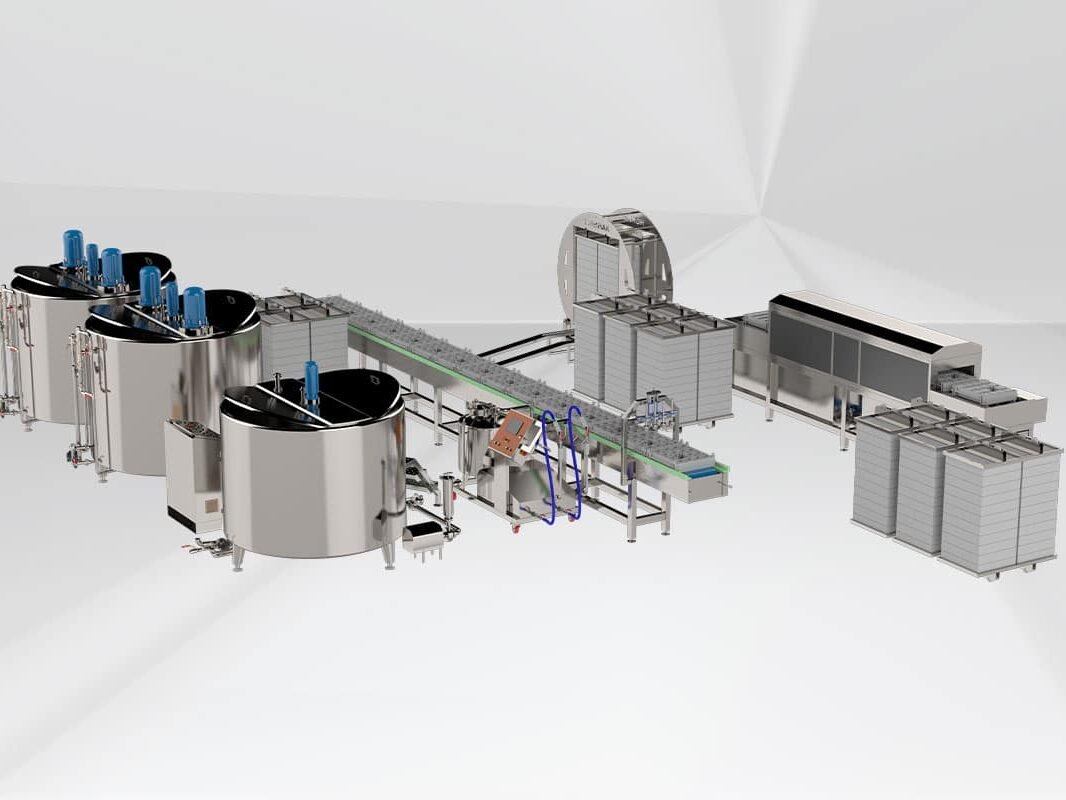

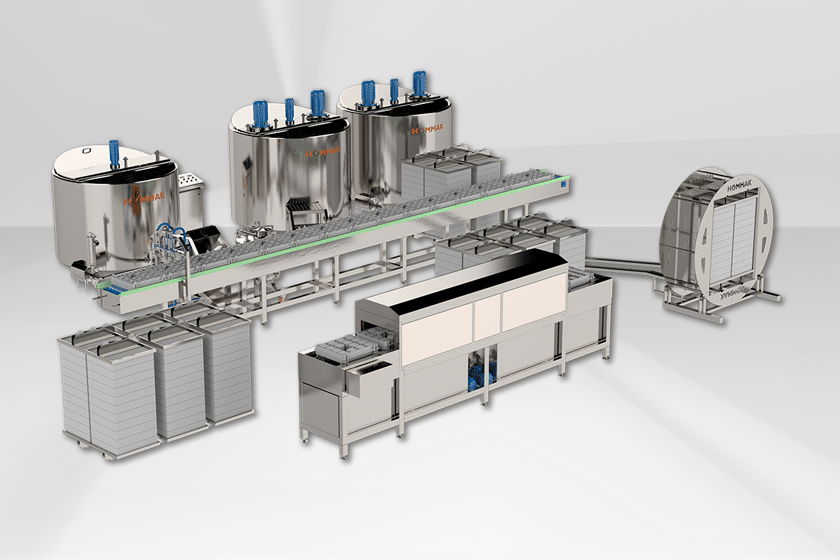

The UF Feta cheese production assembly is an inclusive arrangement of machinery and equipment engineered for producing UF Feta cheese. The assembly encompasses various machines, including a cheese vat, a cheese press, an aging room, a cheese grader, a cheese molder, a cheese cutter, a cheese curd grinder, a cheese mixer, a cheese slicing machine, a cheese wrapping machine, a separator, a homogenizer, among others. The purpose of the machinery and equipment in the UF Feta cheese production line is to facilitate the creation of an optimal quality product.

The machinery and equipment integrated into the production line have a significant impact on the UF Feta Cheese’s quality. The aging process is integral for the development of the cheese’s flavor and texture. Devices like the cheese press and grader guarantee the cheese’s desired consistency and flavor profile. The cheese molder, cutter, and grinder are key to forming the cheese into the precise shape and size. The cheese slicing machine and wrapping machine play a role in packaging, labeling, and preserving the cheese.

A pivotal part of the UF Feta cheese production line is the high-pressure homogenizer. This machine is responsible for the breakdown and homogenization of milk fat into a uniform product. Additionally, the homogenizer helps to minimize the presence of harmful microorganisms in the milk, thereby ensuring a safe and superior quality product.

HOMMAK UF Cheese Production Line

Our company delivers a comprehensive turnkey UF Feta cheese production assembly, designed with the aim of enabling producers to yield a premium-quality product with unparalleled efficiency. We incorporate state-of-the-art technology and machinery to guarantee the effectiveness and efficiency of the production assembly. Our seasoned team of engineers and technicians stand ready to furnish technical and operational assistance. Additionally, we provide an exhaustive warranty and post-sales service on our product range.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

Our plate pasteurisation and sterilisation systems are designed in a manner which you can safely use in the pasteurisation processes

It is an innovative solution designed for the sector and the need and is the invention of HOMMAK.

Storage tanks are made of stainless steel for the storage of liquid substances.

Labne production plant is a system of machinery and equipment used to process milk and produce labne, a type of yogurt.