Cream cheese has long been a delicious addition to our breakfasts, desserts, and recipes. It has gained fans worldwide with its velvety texture and unique taste. But have you ever thought about what’s behind its perfect consistency? This is the homogenization process and when it comes to this important step, HOMMAK stands out as a pioneer in the world of homogenizer machines.

The Journey of Transforming Milk into Cream Cheese

Milk Pasteurization and Standardization: This is the first step in which harmful bacteria are killed, ensuring the milk is safe for consumption and has a consistent fat content.

Homogenization: A very important step in which the protein and fat of milk are perfectly combined. This ensures that the final product has a smooth and consistent texture; This is especially important for cream cheese.

Preparation for Cheese Making: Processed milk is tempered to fermentation temperature where additives such as mesophilic culture and rennet are added. After fermentation, a curd is formed, which is mixed to obtain a homogeneous structure and ensure even distribution of the ingredients.

High Temperature Process: The curd is heated and held at high temperatures to denature the whey proteins and integrate them into the cheese matrix. This step is very important for the texture and longevity of the cream cheese.

Separation and Addition: Whey is separated from the cheese curd using a double cream cheese separator. Once separated, additives such as gum, salt or other ingredients are mixed into the double cream fresh cheese. Packaging at high temperatures provides longer shelf life.

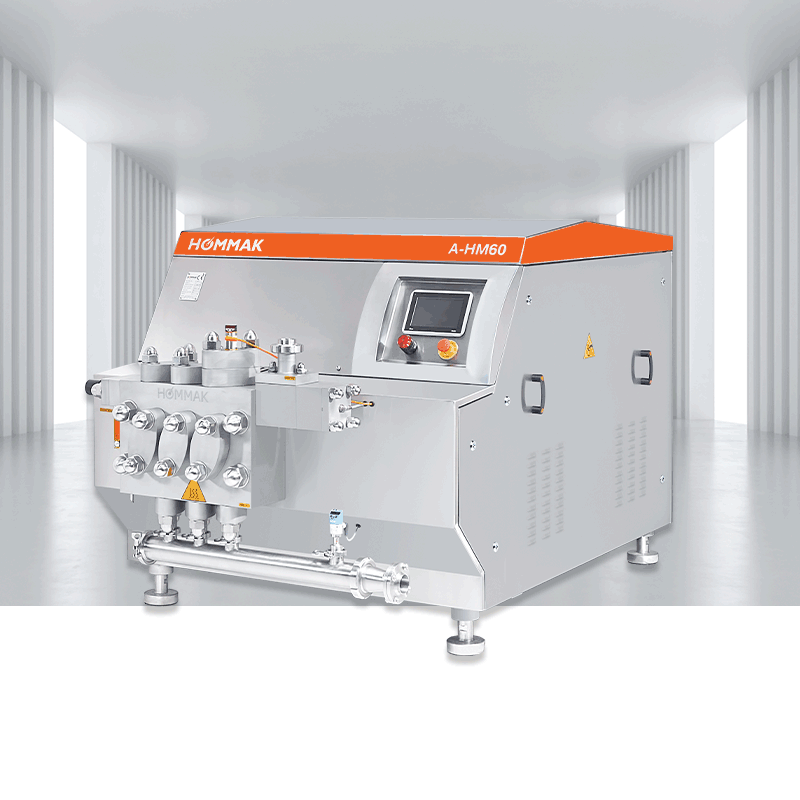

Why HOMMAK Homogenizers?

Global Expertise: HOMMAK Makina is the world’s largest homogenizer manufacturer under one roof, with its vast experience in homogenization. Its products have reached more than 100 countries and served more than 3,000 satisfied customers.

Guaranteed Quality: HOMMAK ensures first-class quality, ensuring your cream cheese stands out in the market, thanks to its continuous investment in modern machinery, R&D, design and product development.

Diverse Product Line: Besides homogenizers, HOMMAK also offers a range of machines such as high shear mixers, pasteurizers, ricotta systems and more, ensuring that every step of your production process is supported by the best machines available.

Passionate Team: HOMMAK’s experts are not only knowledgeable, but also passionate about ensuring that every machine they produce is of the highest quality. Their commitment to excellence has earned them recognition as global experts.

References: More than 3,000 leading brands in various sectors, from dairy products to cosmetics, vouch for HOMMAK’s quality and service.

Solution

Homogenization is not just one step in cream cheese production; is the spine. When it comes to achieving perfect consistency and quality, HOMMAK Homogenizers have proven to be the industry’s gold standard. Therefore, for manufacturers aiming to produce the best cream cheese, adapting to HOMMAK is not only a choice but also a promise of excellence.