Yogurt, an essential staple in diets worldwide, combines culinary finesse with scientific precision. The secret to its universally adored texture and taste lies significantly in the production process, particularly in the role of homogenization. Enter the Hommak Homogenizer, a pivotal tool in achieving that perfect yogurt consistency. This article explores the unmatched efficiency of Hommak Homogenizers under high-pressure conditions in enhancing yogurt production.

Understanding Homogenization’s Significance

Homogenization is crucial in yogurt manufacturing, ensuring milk’s fat molecules are uniformly distributed rather than forming a separate layer at the top. This process guarantees the yogurt’s consistent creaminess. Hommak Homogenizers excel in this aspect, utilizing high-pressure technology to maintain an even distribution of fat molecules, resulting in a smoother, creamier yogurt.

Advantages of High-Pressure Hommak Homogenizers

Enhanced Smoothness: Hommak’s high-pressure homogenization delivers an unmatched silky texture, eliminating any lumps or gritty textures for an enjoyable eating experience.

Consistent Flavor: The uniform distribution of fats and solids under high pressure ensures every spoonful of yogurt is flavorful, offering a consistent taste throughout.

Improved Shelf Stability: Yogurt that remains mixed and doesn’t separate over time is more appealing to consumers. High-pressure homogenization plays a pivotal role in extending yogurt’s shelf life.

Optimized Fermentation: Hommak Homogenizers promote even distribution of fermentation bacteria, ensuring a uniform fermentation process for balanced, high-quality yogurt.

Features of Hommak Homogenizers in Yogurt Production

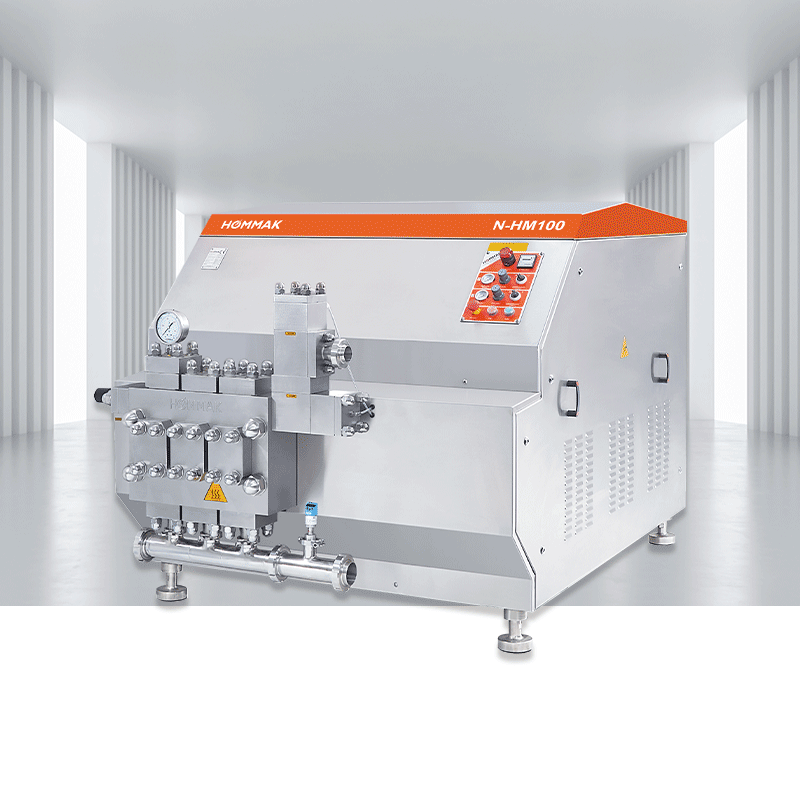

Hommak Homogenizers are engineered to meet the specific demands of yogurt production. They incorporate high-pressure processing to ensure thorough mixing of ingredients, from flavors to fruit pieces, ensuring an evenly distributed mix. The high-pressure operation breaks down large particles and integrates them seamlessly into the yogurt, preventing fruit from settling at the bottom and guaranteeing a uniform product.

Benefits for Yogurt Producers Using Hommak

Consistent Quality: Producers can achieve consistent product quality with each batch, reinforcing the brand’s reputation.

Increased Efficiency: Improved mixing and fermentation processes result in higher yields from the same amount of raw materials.

Reduced Wastage: The consistency and extended shelf life minimize the potential for returns and unsold products.

Exploring Hommak Homogenizer Options

Selecting the right Hommak Homogenizer is essential for meeting your production requirements and capacity. Our specialists are ready to assist in choosing the most suitable homogenizer for your needs. If you’re interested in elevating your yogurt production with our high-pressure Hommak Homogenizers and obtaining a quote, contact us today. Let’s achieve creamier, more delicious yogurt together.