The production of cloudifiers, or clouding agents, is an important part of the beverage production process. Clouding agents are used to give drinks a more natural appearance, to mask sedimentation, and to prevent oil “ringing” in storage. High pressure homogenization is the key to achieving the desired effect of these cloudifiers. In this article, we’ll discuss how HOMMAK’s Cloudifiers Homogenizers can help you create the perfect beverage product.

What Are Cloudifiers?

Cloudifiers are generally oil-in-water emulsions that are used to give drinks a natural appearance. They contain citrus oils, vegetable oil, stabilizers such as Arabic gum, and weighting or densifying agents such as resin gums.

The Conventional Mixing Problem

Preparing a pre-emulsion with conventional agitators can lead to several problems. Powders must be added at a controlled rate to reduce agglomeration of particles. Traditional systems don’t produce enough shear to break down agglomerates. Agitation of the solution and dispersion of powders become more difficult as the viscosity increases. Long processing times are required to completely disperse the ingredients and achieve a satisfactory consistency.

The HOMMAK Solution

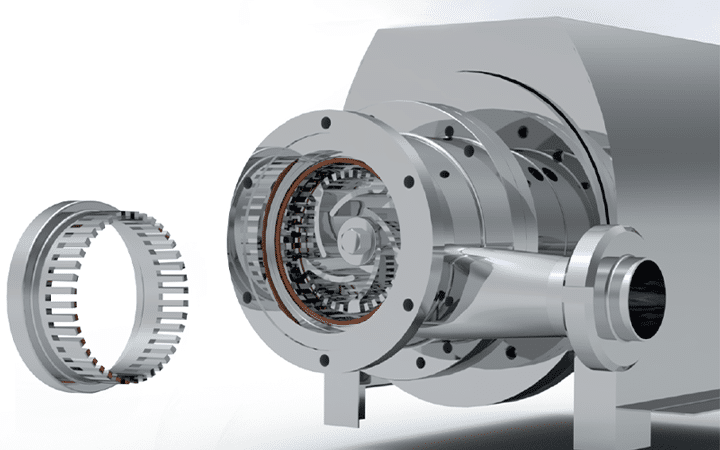

HOMMAK’s Cloudifiers Homogenizers offer the perfect solution to these problems. The high shear action of the rotor/stator work head hydrates and disperses the powdered ingredients, producing a finely dispersed pre-emulsion that a single pass through a high-pressure homogenizer is usually sufficient to achieve the desired globule size.

The Benefits of Cloudifiers Homogenization

Using HOMMAK’s Cloudifiers Homogenizers, you can expect several benefits, such as:

- A single pass through a high-pressure homogenizer is typically sufficient to achieve the desired globule size.

- In some cases, the high-pressure homogenizer can be eliminated altogether.

- The ability to start and stop the process quickly for processing of ingredients on demand.

- Agglomerate-free mix.

- Consistent product quality and repeatability.

- Stable pre-emulsion.

- Maximized yield of raw materials as thickening agents are fully hydrated and other ingredients are fully dispersed.

- Dramatic reduction in mixing times.

- Improved vessel hygiene.

Make the Right Choice with HOMMAK Homogenizers

If you’re looking for a reliable and efficient homogenizer for your cloudifiers production, HOMMAK’s Cloudifiers Homogenizers are the perfect choice. With their high performance and maximum yields, they are sure to help you create the perfect beverage product.