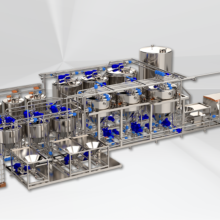

The Hommak Vacuum Processing Production Line revolutionizes material transformation by expertly reducing both temperature and pressure. This advanced equipment suite, featuring high shear mixers, pumps, valves, and filters, along with a precisely engineered vacuum chamber, works in unison to create a vacuum. This significantly lowers the material’s pressure, facilitating its efficient processing into the desired form.

Materials vary, and so do their processing needs. Foods and pharmaceuticals benefit from our high-pressure homogenizer, which uses intense pressure to break down solids into finer particles. For chemical substances or liquids, our high shear mixer is ideal, separating components with its rapid spinning action.

The performance of our Vacuum Processing Unit is unmatched, thanks to the superior quality of our machinery. With high-grade pumps and valves ensuring efficient operation, and our commitment to regular maintenance, our system guarantees optimal performance. Our high-pressure homogenizer is crucial for achieving uniform particle sizes, ensuring consistent product quality.

Vacuum Processing Production Line

In the Hommak Vacuum Processing Production Line, every step is designed for maximum efficiency and effectiveness:

- Vacuum Chamber: The process starts by placing the material in the chamber, where a vacuum is created, setting the stage for processing.

- Pumps: These are essential for reducing the chamber’s pressure, creating the perfect conditions for material processing.

- Valves: Managing material flow is crucial, and our valves ensure optimal distribution for processing.

- Filters: Key to the process, our filters purify the substance, removing contaminants to ensure quality.

- Homogenizer: Utilizing high pressure, the homogenizer fragments the material into finer particles, enabling further processing and refinement.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

HOMMAK Makine developed the Hommix Powder-Liquid Blender as a result of long R&D studies.

Storage tanks are made of stainless steel for the storage of liquid substances.

Caramel sauce adds color and flavor to your products and improves their presentations.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.