Centrifugal pumps are mechanical marvels designed to facilitate fluid movement through the transfer of rotational energy from one or more rotors, otherwise known as impellers. Fluid is pulled into the rapidly spinning impeller along its axis, only to be flung outward by centrifugal force along the circumference via the impeller’s vane tips. Through this process, energy is hydrodynamically transferred in centrifugal pumps.

Centrifugal pumps: Fluid Motion with Mechanical Finesse

Over 20 years of experience

More than 3500 references worldwide

Superior quality and Competitive pricing

HOMMAK Centrifugal pumps are indispensable in industries such as dairy production, beverage processing, cosmetics, and pharmaceuticals. These pumps serve as a key process component, with milk and dairy production plants being the prime users. For this reason, our pumps often earn the moniker of ‘stainless milk pump’.

Beneficial Features of HOMMAK Centrifugal Pumps

- Constructed with AISI316L for all components in contact with the product.

- The body and additional parts are made from AISI304L.

- A perfect fit for handling a variety of products such as Milk, Juice, Cream, Whipping Cream, and Olive Oil.

- Capacity ratings are designed for products with a density range of 0.7-1.1/cm3.

- Capable of operating at pressures up to 10 bar.

- The low NPSH value helps in preventing early cavitation in the pump.

- Energy-efficient due to optimized speed control.

- Open impeller design engineered for appropriate product handling.

- Features high-efficiency IE3 motors.

- Designed for easy removal of the mechanical seal unit from the front.

- Flush unit is easy to retrofit.

- Pump shaft is safeguarded by a wear sleeve.

- Uniformity in mechanical seal sizes across the entire pump series.

- Choice of seal face materials: carbon/silicon carbide (standard), or silicon carbide/silicon carbide.

Key Features of HOMMAK Centrifugal Pump

- Crafted for Corrosion Resistance

- Built for Maximum Energy Efficiency

- Engineered to Provide Smooth Flow

- Reliability Proven through Testing and Use

- Designed for Low Maintenance Cost

- Simple Design with Few Moving Parts for Extended Service Life

- Direct, High-Speed Drive via an Electric Motor

- Continuous, Pulsation-Free Delivery of Fluids

- Compact Power Concentration for Space Efficiency

- Designed for Quiet Operation with Balanced Mass and Lack of Oscillating Masses

- Flow Rate Easily Adjustable through Outlet Valve or by Adjusting Rotational Speed.

Design Attributes and Characteristics

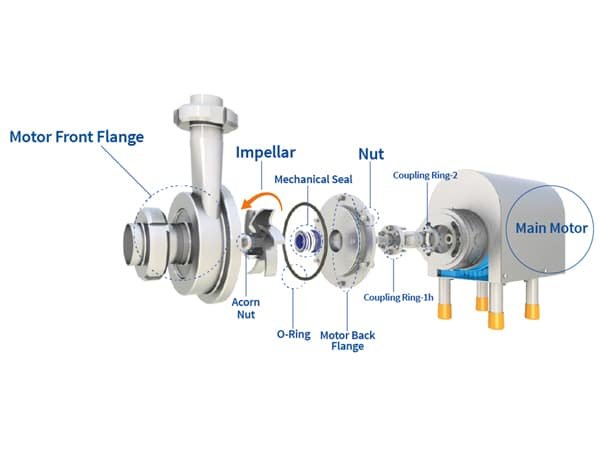

HOMMAK’s Q-CP series comprises a selection of close-coupled centrifugal pumps, noted for their hygienic design, compact size, and remarkable efficiency. Their construction involves cold-formed stainless steel for the casing, impeller, mechanical seal, pump cover, lantern, and shaft, which is mechanically compressed to attach to the motor shaft. The IEC-standard compliant motor is protected by a stainless steel shroud and is set on height-adjustable legs designed for hygiene.

Get in Touch!

Related Products

Fluid products in heterogeneous (non-homogeneous) structures pass through the narrow gap under high pressure.

HOMMAK Makine developed the Hommix Powder-Liquid Blender as a result of long R&D studies.

High-pressure pumps are ideal for transferring high density and viscosity products. It is used as the feeder for the tower in the production of milk powder, food powders, chemical powders, and other powder types.

It is an innovative solution designed for the sector and the need and is the invention of HOMMAK.

It is designed to allow you to fill yogurt in the desired volume or weight, with 0.1% precision and high speed.

HOMMAK Homogenizers are manufactured by selecting the valve design and material to meet the needs of the sector in which it will be used.

HOMMAK laboratory type homogenizer has a portative and transportable structure. It enables you to improve your current products, test the effect of homogenization on products, and get optimum results by determining the best process parameters.

HOMMAK pilot plant homogenizers are designed for limited production and R&D studies.

Our plate pasteurisation and sterilisation systems are designed in a manner which you can safely use in the pasteurisation processes