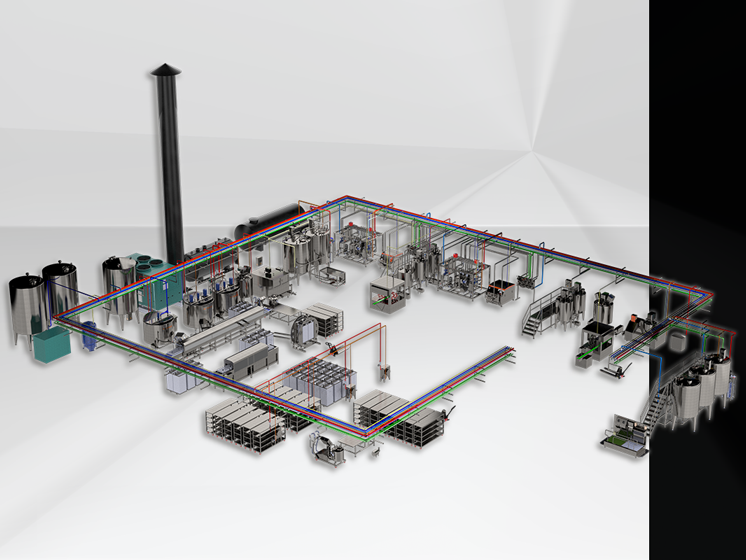

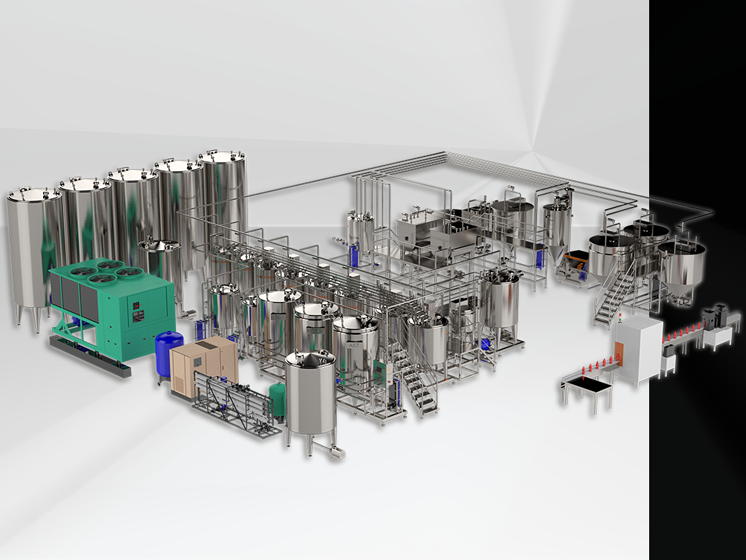

The equipment used in a dairy plant includes pasteurizers, homogenizers, separators, tanks, pumps, and other specialized machinery. The process of a dairy plant generally includes pasteurization, homogenization, separation, standardization, cooling, and packaging. The machinery and equipment used in a dairy plant have a direct effect on the quality of the products they produce.

Dairy Plant

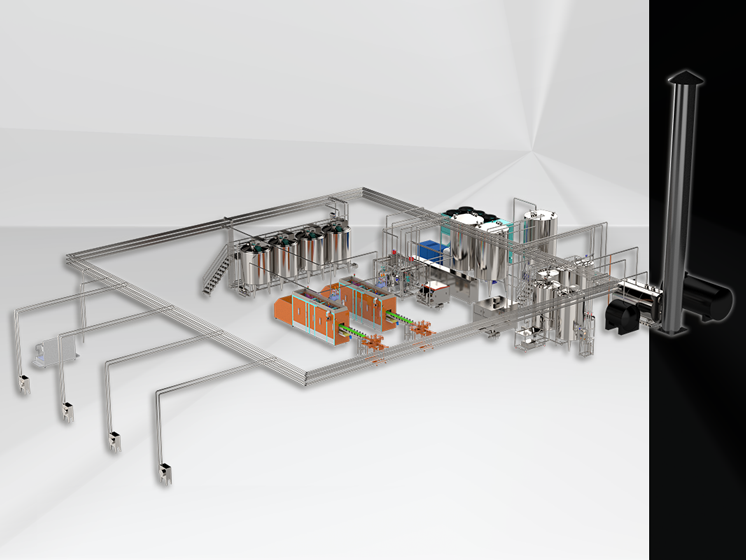

Ice Cream Plant

In the modern sense, the main developments in the ice cream production process began with the development important Technologies such as cooling, pasteurization and homogenization after the 20th century.

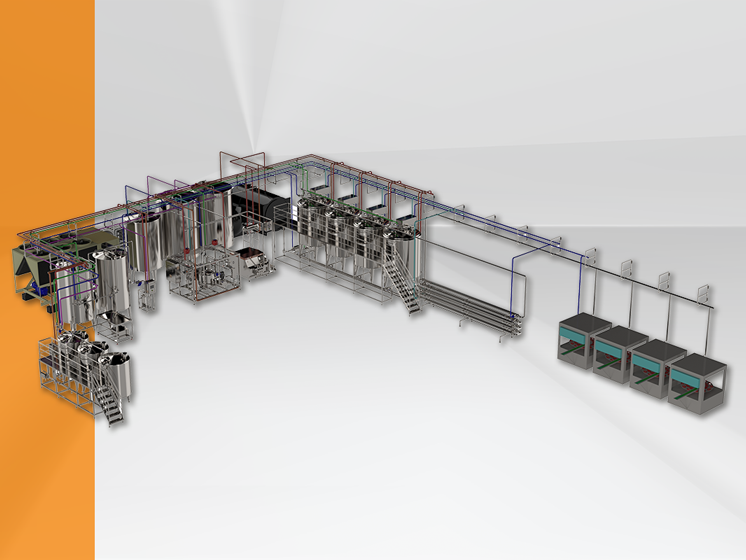

Yogurt Plant

This machinery is used to process and package yogurt in a factory setting. The yogurt plant typically includes equipment such as homogenizers, pasteurizers, fermentation tanks, filling machines, packaging machines, cooling systems, and other necessary components.

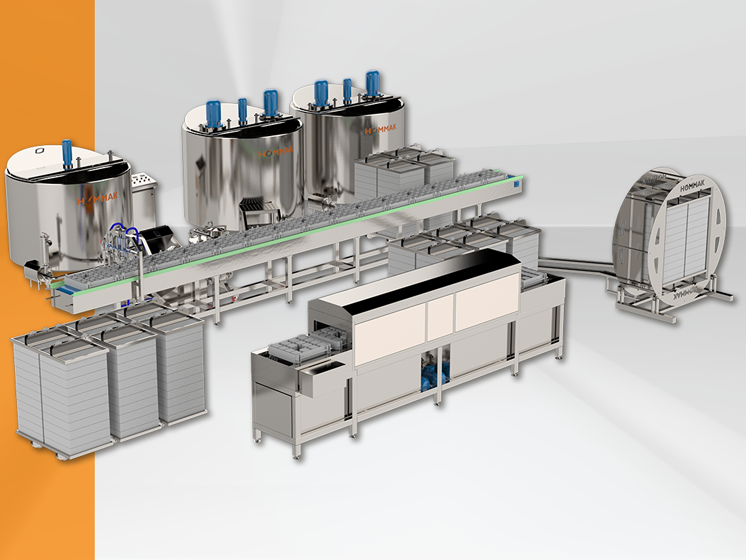

Fruit Yogurt Plant

It includes equipment for processing fruits like pulping and pasteurizing as well as equipment for producing yogurt such as fermenting, homogenizing, and packaging. The process of fruit yogurt production starts with cleaning and sorting the fruits. The fruits are then pulped and pasteurized before being mixed with other ingredients such as sugar, milk, and cultures. The mixture is then homogenized and fermented before being packaged and pasteurized again. The machinery and equipment used in a fruit yogurt plant affects the quality of the finished product. A high pressure homogenizer is used to evenly mix ingredients, creating a homogenous product that is more consistent in texture, flavor, and color.

Labne Production Plant

The process involves pasteurizing the milk, adding specific bacteria strains, incubating the milk, cooling it, and finally straining it through a cheesecloth. The equipment used in a labne production plant includes a pasteurizer, incubator, cooling tanks, homogenizer, and cheesecloth.

UF Cheese Production Line

It includes a variety of machines, such as a cheese vat, a cheese press, an aging room, a cheese grader, a cheese molder, a cheese cutter, a cheese curd grinder, a cheese mixer, a cheese slicing machine, a cheese wrapping machine, a separator, a homogenizer, and more. The machinery and equipment used in the UF Feta cheese production line is designed to help producers create a high-quality product.

Fruit Juices Production Plant

It includes a range of equipments and machinery which are used for squeezing, blending, filtering, pasteurizing and bottling fruit juices. The equipments used in a fruit juices production plant includes a fruit crusher, juicer, blending tank, filter, pasteurizer, homogenizer, pumps, valves, bottle filling machine, and a packaging machine.

Ketchup Line

It typically includes food processing machines, such as blenders, homogenizers, mixers, conveyors, and other equipment. The entire production line is automated and controlled by a computerized system. The machines used in the line process the ketchup ingredients and mix them into a homogeneous paste. The homogenized paste is then heated, cooled, and packaged.

Ketchup & Mayonnaise Full Automatic Production Line

Ketchup & Mayonnaise Full Automatic Production Line is a fully automated line of machines and equipment that can process ketchup and mayonnaise from raw ingredients to finished products. The production line includes machines for mixing and blending ingredients, homogenizing the mixture, and filling, capping, labeling, and packing the final product. The production line typically includes mixers, homogenizers, filling and capping machines, labeling machines, and packaging machines.

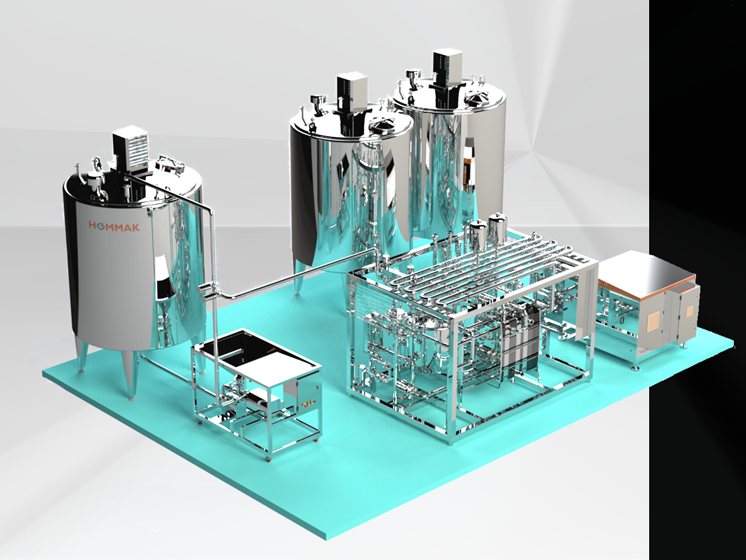

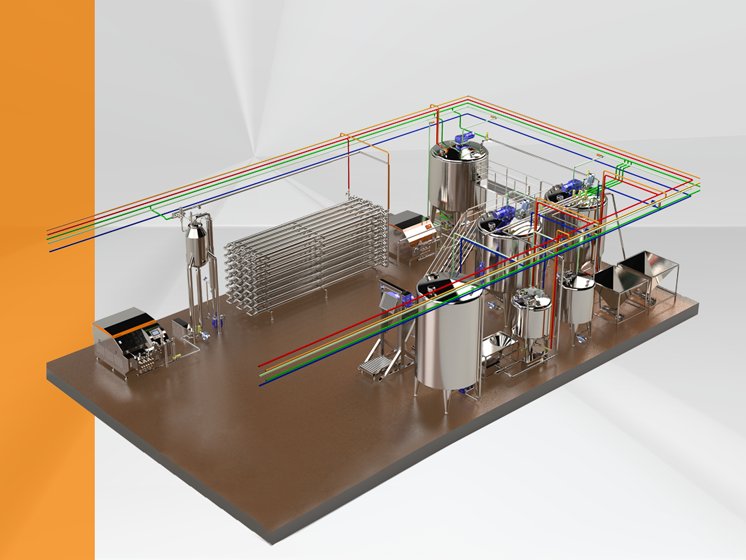

CIP Plant

The equipment used in the CIP plant includes pumps, tanks, valves, meters, pipes and other components. The pumps are used to circulate cleaning solutions and other liquids through the system. Tanks are used to store and mix the cleaning solutions. Valves are used to control the flow of fluids and regulate the pressure. Meters are used to measure the flow of the cleaning solutions. Pipes are used to transport the cleaning solutions throughout the plant.